Half-round I-Rod is available in 5-foot or 10-foot lengths or pre-cut-and-drilled for any standard pipe U-bolt.

Corrosion at pipe supports is one of the leading causes of process piping failures. Not surprisingly, beam supports and saddle clamps have historically caused the majority of problems. They have these undesirable features in common:

- Crevices – the formation of a crevice at the pipe surface.

- Water entrapment – water is trapped and held in constant contact with the pipe surface.

- Poor inspectability – these supports are virtually impossible to paint or maintain, and visual inspections and NDT are often difficult.

- Galvanic couples – even when both the pipe and the support are the same steel, the metallurgical differences can still provide enough potential to drive a galvanic corrosion cell.

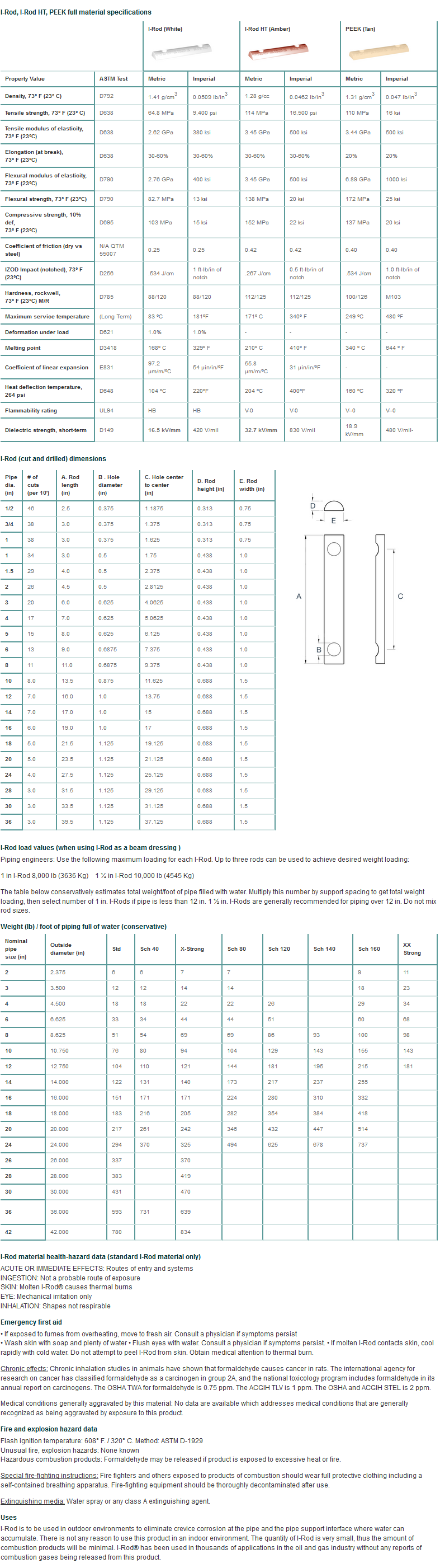

I-Rod is the solution. I-Rod, a durable, extruded thermoplastic cut into a half-round rod, is the key component in all of Deepwater’s I-Rod brand pipe supports. It is available in 10-foot lengths or cut-and-drilled for use with standard-size pipe U-bolts.

There are three different diameter sizes for I-Rod: 0.75 inch, 1 inch, and 1.5 inch, as well as a high-temperature version for process piping operating above 200 °F.

The Nu-Bolt Assembly is our most popular I-Rod product, providing corrosion protection at I-beam supports. For Grinnell clamps and pipe saddles, the newest addition is the I-Rod Clip, designed to clip onto new and existing saddle-clamp-style supports or inside clamps.